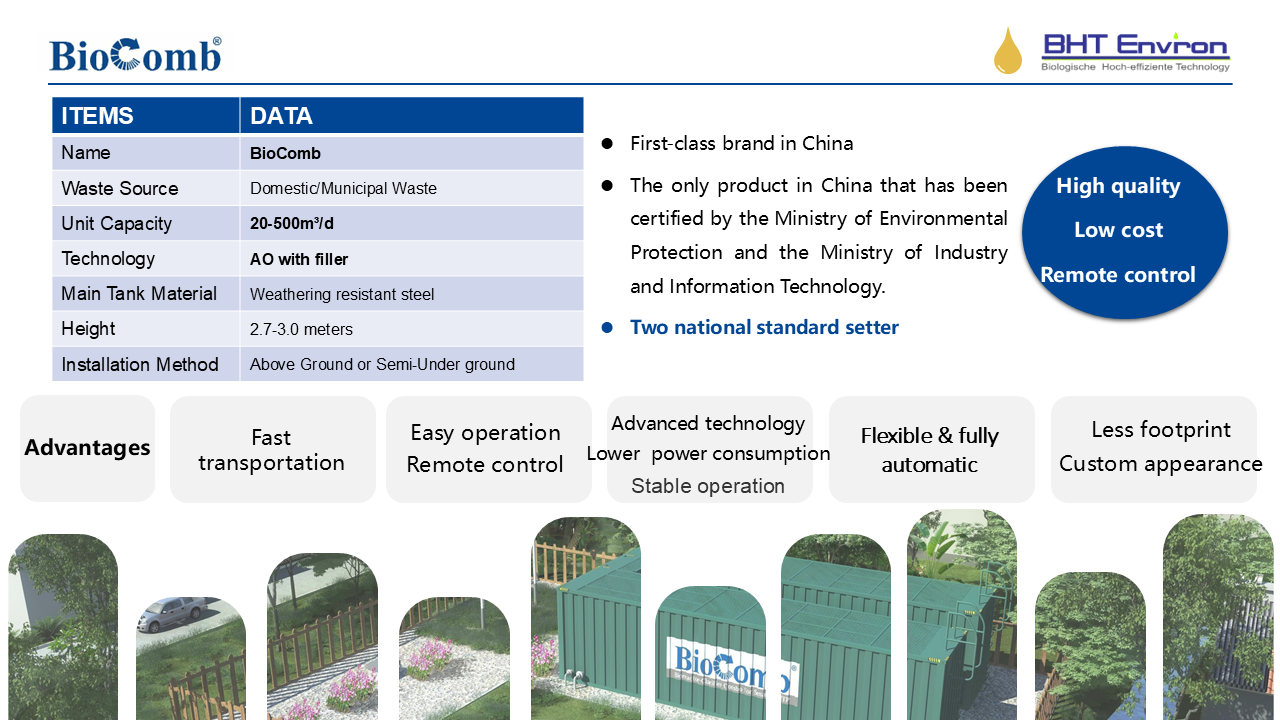

BioComb integrated wastewater treatment equipment

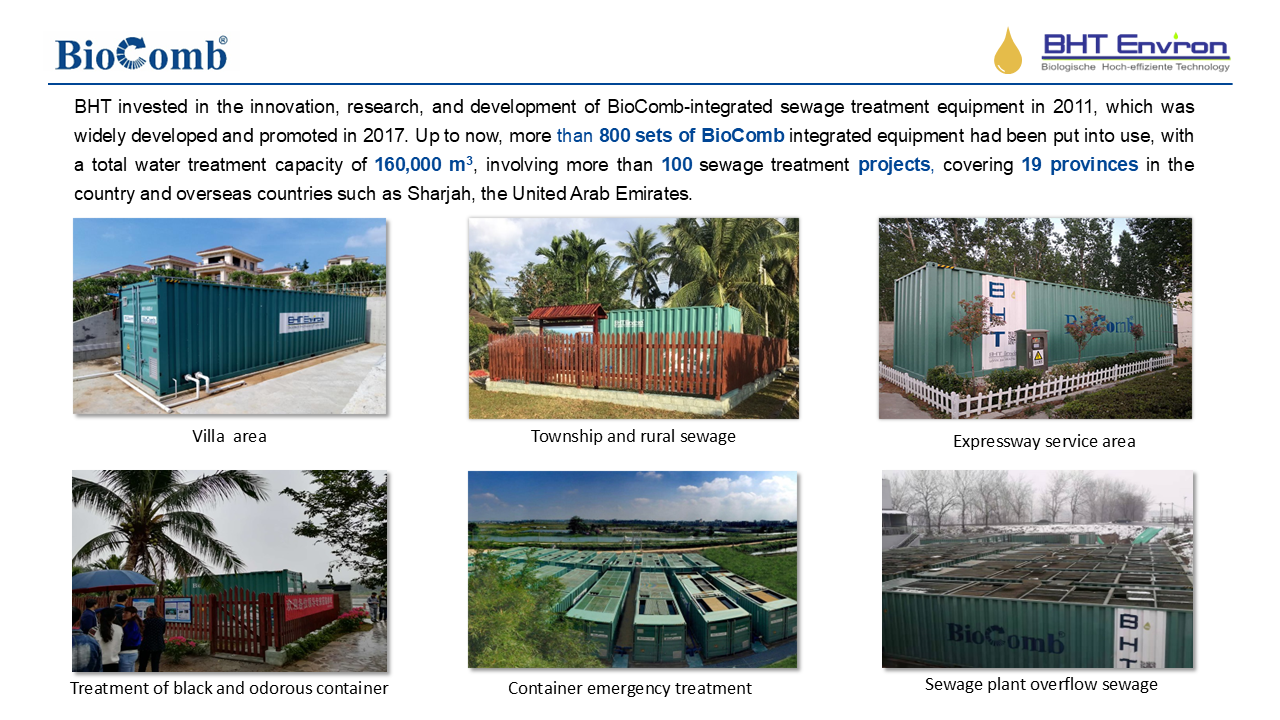

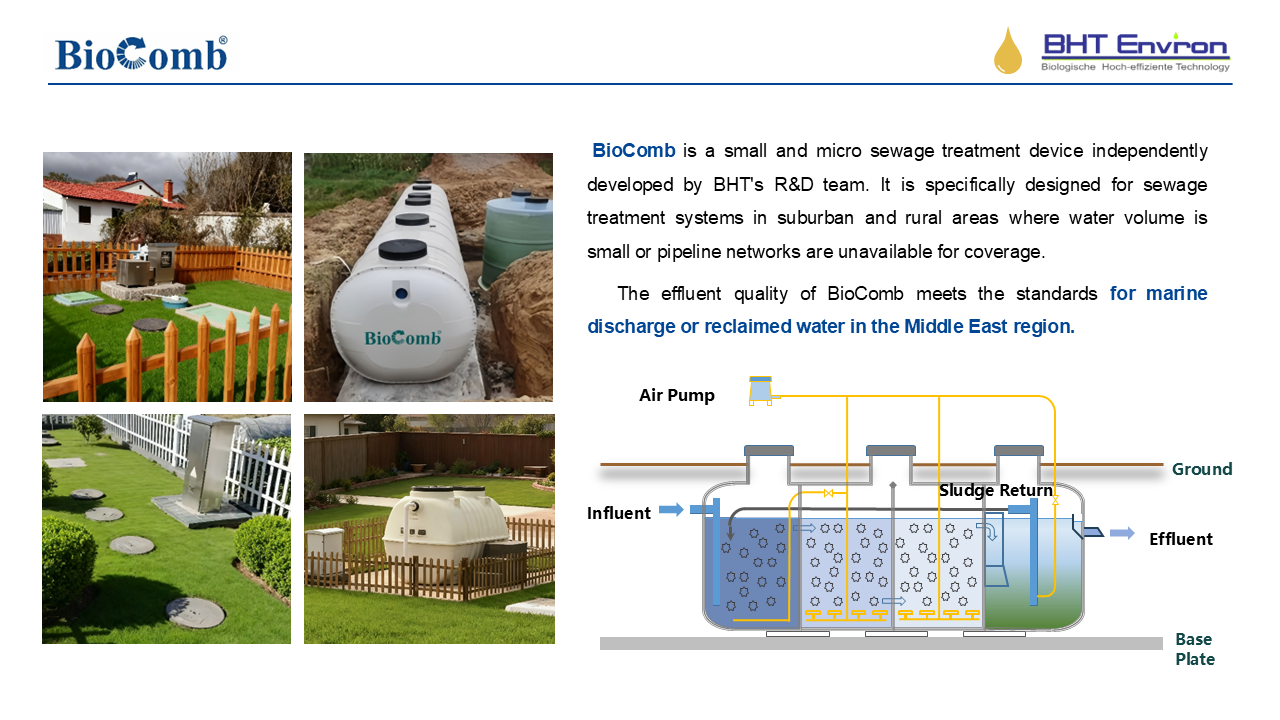

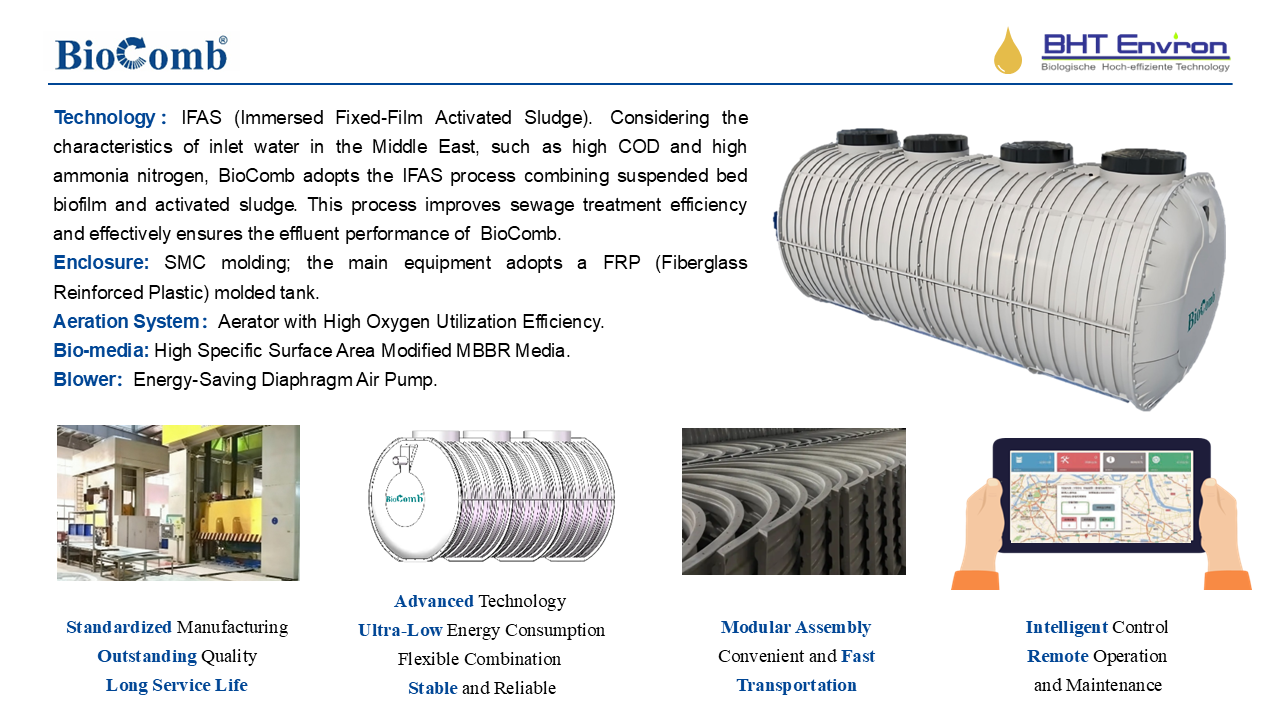

The BioComb integrated wastewater treatment equipment is available in two types: one is the containerized above-ground installation, which is suitable for large water treatment volumes; the other is the buried tank type, which is designed for relatively smaller water treatment volumes.