Process Package Technology and Investment Service --- Innovative Operational Practices of BHT Environ

As a technology company focusing on processes, BHT Environ has adopted innovative operational practices of process package technology and investment service in providing customers with all-inclusive process design, patented or proprietary equipment for key components and related technical consulting and service, commissioning and training. These innovative operational practices have been well received by users and industry. Water-Industry Market recently had an interview with Mr. Pan Jiantong, Chairman and General Manager of Beijing Bohuite Environmental Technology Co., Ltd., (BHT Environ), who described his understanding of the current wastewater treatment industry, and shared his ideas on the main business and future strategic direction of BHT Environ.

Wastewater discharge has kept rising along with China's continuous industrialization, urbanization and rapid economic growth. Environmental protection and industrial development are posing greater demand for protection. In the future, the wastewater treatment technology has great potential of development, as the wastewater treatment sector will need more investment and more advanced technology.

Golden Decade Expected for Environment Protection Sector in New Normal Phase

At present, ecological and environmental protection is undergoing dramatic changes characterized by diverse means and practices of environmental governance and modernized management. Meanwhile, many government reform initiatives will release more opportunities for the environmental protection market. Talking about the industry’s future trends in this context, Pan Jiantong pointed out that China’s current environmental protection industry is still under the guidance of national policies for the industry. The investment by the government in environmental protection in the 13th Five-Year Plan period is about 3 times that in the 12th Five-Year Plan period, accounting for 4.5% of the yearly GDP. In contrast, the investment in environmental protection reached up to 10% of the yearly GDP in western developed countries during their transition period. There is a huge room for growth of the environmental protection industry, along with further economic development and public awareness of environmental protection. As to the wastewater treatment industry, “wastewater treatment industry is an important part of environmental protection industry, accounting for more than 1/3 of the total investment in the industry in more than. The environmental protection industry is expected to enter a golden decade in the New Normal phase, facing both opportunities and challenges. Restructuring and reshuffle will be seen among environmental protection enterprises. Large enterprises are likely to undergo mergers, reorganization and splitting. Low-end production-based enterprises will be gradually phased out. The future trend is the combination of capital, cross-discipline interaction technology + appropriate business models, which will take the lead of the whole industry’s development,” said Pan Jiantong.

More Stringent Standards Accelerate Survival of the Fittest in the Industry

In view of increasingly stringent standards on wastewater treatment, Pan Jiantong believes that the market will be guided by policies in the future, as the government has strengthened penalty collection and monitoring for incompliant emissions and discharge. The increasingly stringent requirements for emissions will gradually eliminate outdated processes with high energy consumption, large land use, and deficiencies in functionality. The application and promotion of new technologies will gradually become market-oriented, driving technical innovation and the application of novel practices.

As for the rural market, Pan Jiantong pointed out the mismatch between emission standards and funding and management in less developed regions, because urban wastewater discharge standards are referenced in rural wastewater treatment, for which no specific local standard is available. The wastewater in rural areas and small towns is a result of rapid urbanization, which has reached 55% at present by now. The government requires unified implementation of urban emission standards mainly considering the capacity of the receiving waters and the environment, and it impossible to formulate emission standards specific to certain areas in the short term. For this reason, Pan Jiantong appealed and suggested that we could flexibly adjust individual indicators such as those for TN and TP in wastewater discharge standards based on the local economic development level and environmental capacity, and encourage local treatment and reuse whenever possible.

Reliance on Distributed Treatment of Rural Wastewater Complimented by Centralized Treatment

According to Pan Jiantong, the difficulties in rural wastewater treatment are mainly reflected in the following aspects. Firstly, the investment is high in pipeline and collection systems, while there are difficulties in their construction. Secondly, the water volume is unstable, adverse to continuous operation; traditional biochemical denitrification is hardly possible in winter in northern regions due to low water temperature. Thirdly, there are insufficient professional personnel for management in rural. In his view, the greatest difficulty in rural wastewater treatment lies in management instead of technology. Due to lack of technical personnel, it is very difficult to find a suitable process. At present, another prominent problem in rural wastewater treatment is that the costs of operation and maintenance are relatively high and the low level of field operation. In addition, farmers lack of motivation as they get no immediate benefit.

In his opinion, a future trend of rural wastewater treatment is full recovery of energy and effective components, which impose four requirements in terms of technology. Firstly, the operational costs of processes and equipment should be low and acceptable to farmers. Secondly, the management and maintenance should be simple and really dummy-proof. Thirdly, the effluent should be stable and reliable. Fourthly, the installation and startup should be fast, and the systems should be capable of self-healing.

Two major operational practices can be summarized. In the first one, the operation is controlled by the local governments, communities or farmers. In the other, a mature and reliable operation system is established, requiring not only an experience operation team but also coordination based investment, management rules, large databases, etc. He believes that the fast growing Internet plus will lead to dramatic changes to the industry in the next 10 - 20 years. BHT Environ will also actively explore the possibilities with the Internet plus and work on new operational practices in following the trends of technology.

In Pan Jiantong's view, rural wastewater has different characteristics specific to individual regions as China has a vast territory. There are huge differences between the south and the north, and between the east and the west and they have different water consumption per capita, water quality and temperature. Therefore, it is difficult to define a unified technology or process for all rural wastewater. In the future, most rural wastewater should be treatment in a distributed manner, with moderate scale of centralized treatment, to solve the problems of rural wastewater discharge and reuse at the minimum cost. Wastewater contains rich nitrogen and phosphorus, so areas without heavy industry should consider combining wastewater treatment and agriculture. Water is the spirit of rural areas. A trend is turning wastewater treatment into landscaping, and turning pollutants into resources.

Considering the characteristics of rural areas, the processes used in rural wastewater treatment should be made available with moderate investment, featuring low operational costs, simple management and maintenance, and reduced sludge discharge. In terms of management, the processes should allow relatively extensive and flexible operation, and wide thresholds to adapt to lack of professionals in rural areas.

As for management, operation and investment of rural wastewater treatment, Pan Jiantong notes that investors in the rural wastewater market usually aim at strategic investment. Focusing on the future, they are now trying to seize the market resources while paying little attention to return in the short term. However, short-term profitability is possible when investment is combined with right technology and business models. Rural wastewater treatment is characterized by a large number of distributed sites. Considering this, it is advisable to establish mechanisms for consolidating site operation by country or town to amortize labor costs to the greatest extent.

The long-term trends of rural wastewater treatment models include outsourcing and consolidated operation to minimize labor costs.

BioDopp Process: Highlight of BHT Environ’s Core Technology

BHT Environ is a technology company focusing on processes, with biochemical technology as its core, including the BioDopp micro-aerobic process and related series of anaerobic technology, cold-resistant bacteria, salt-tolerant bacteria and other engineering bacteria technology, electro-catalytic oxidation, surfilter filters, contact oxidation, and other combined technology. According to Pan Jiantong, the BioDopp process is the core technology of BHT Environ. Originating in Germany, it has been commercialized quickly in China and some other developing countries. It is an efficient biochemical wastewater treatment technology combining removal of carbon, nitrogen and phosphorus, and sedimentation and other functions, developed by Chinese and Germany researchers through leveraging advantages from various biochemical processes from expertise in long-time wastewater treatment projects, based on the ideas of full liquid backflow and integrated structure of oxidation ditches, use of different functioning zones of A2/O, with the help of CASS pre-process biological selection as well as efficient aeration, with the innovative air lifting technology as the driving source. The BioDopp process is characterized by a small footprint, low energy consumption, stable and reliable operation, and simple operation and maintenance. Compared with traditional technology, it is also resistant to impact and recover quickly. A course of biochemical treatment allows degradation to superior indicators of effluent. The BioDopp process and related technology have been mainly used in recent years in industries of petroleum, chemical, coal chemical industry, pharmaceutical, printing and dyeing, municipal works, etc. At present, the process has been adopted in wastewater treatment projects of many petrochemical and coal chemical enterprises, including PetroChina, Sinopec, Henan Coal Chemical Industry and Datang Energy Chemical. It is also widely applied in treatment of municipal wastewater in BOT projects and of industrial park wastewater. It has demonstrated satisfactory performance and energy saving benefits. Along with the rapid development of industrial parks and a new round of update, expansion, and renovation of wastewater treatment facilities, the government is attaching greater important to wastewater treatment.

For the rural wastewater treatment market, BHT Environ has launched BioComb integrated containers, which are designed by following the concept high level integration of treatment units and truly dummy-proof management. The most noteworthy advantage of the equipment is that it saves energy consumption by 40% compared with the conventional process, in addition to high standard of discharged water, a small footprint, and ease of management and maintenance.

Potential Energy Neutral Design with BioDopp + BioChar

Energy wastewater treatment plants have been run at the industrial scale in North America. As explained by Pan Jiantong, an energy-neutral wastewater treatment plant means that energy is fully recovered from the wastewater or sludge, which is used for running wastewater treatment plant, so that the whole plant almost requires no energy from the outside. The combination of BioDopp + BioChar ensures that the electric power generated with sludge pyrolysis is used for the wastewater treatment plant’s operation. Moreover, the BioDopp process consumes only half energy compared with traditional process. As a result, the whole wastewater treatment plant requires no electric power from the outside. Though no plant energy-neutral wastewater treatment plant has been in operation, certain investors are interested in cooperation with local governments to build demonstration of energy-neutral operations with an all-process solution. The successful development of the BioChar sludge pyrolysis technology has further extended the industrial chain. On the one hand, it has reduced of the amount of sludge; on the other hand, the energy produced is used by the wastewater treatment plant to achieve energy recycling. Leveraging its technology and R&D strengths, BHT Environ is to invest in energy-neutral wastewater treatment plants with an optimal technology chain, aiming at becoming one of the world’s leading technology developer and operator with a moderate scale and distinctive features in wastewater and sludge operations.

Innovative process package service model

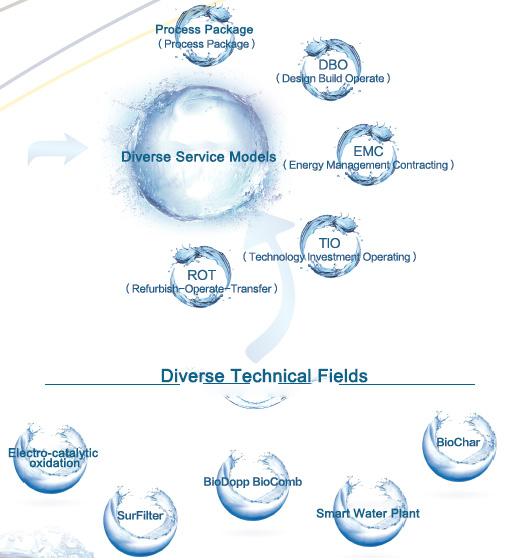

“As a technology provider, we often stand behind the water companies and project companies, and do not access the market directly. However, as project owners are gaining better specialty knowledge, the model of process packages has been emerging in the industrial wastewater treatment field, enabling the greatest control over the process and effective reduction of investment. That is, project owner directly work with technical providers. Currently, BHT Environ provides process packages service to customers, with all-inclusive process design, patented or proprietary equipment for key components and related technical consulting and service, commissioning and training. In the future, we will also participate in other cooperation models, such as DBCO (design, building, commissioning and operation) and EMC (energy management contract). BHT Environ will be engaged in all-inclusive TIO and work with investment companies and project owners under multi-party frameworks,” said Pan Jiantong.

By now, most of the projects undertaken by BHT Environ adopt the BioDopp process, including dozens of typical engineering cases, covering municipal, industrial and small town wastewater treatment, with industries include petrochemical, coal chemical, printing and dyeing, food, pharmaceutical, etc. In recent years, a large number of municipal and industrial park wastewater treatment projects are being planned and built with technology from BHT Environ and total capacity soon to exceed 1 million tonnes per day. The effluent of these projects is designed as per the standard of class 1A of urban wastewater discharge. At the same time, nearly ten projects of rural wastewater treatment have been built or are being built with the BioComb technology, which are housed in standard containers. Many scientific and technological achievements have been obtained and well received by design institutes and customers. (Source: Water-Industry Market)